TL;DR: This study explores the use of three-photon direct laser writing (DLW) to fabricate high-performance quantum dot (QD)-polymer filters, overcoming limitations of traditional two-photon processes. By utilizing a 1035 nm laser, the researchers achieved deeper penetration, higher resolution, and reduced thermal effects, enabling the creation of complex micro/nano structures with enhanced optical properties. The findings highlight the potential applications of these QD-polymer filters in optical devices, sensors, and photonic technologies, paving the way for future advancements in the field.

Context: Mixing nanoparticles into photoresists is a sure-fire method to increase the refractive index of organic/polymer photoresists. Loading high nanoparticle content into photoresists is tricky from a material science point of view because of the aggregation between nanoparticles at high concentrations. The aggregation effects could be improved with solvent selection, surface functionalization of nanoparticles, and careful preparation procedures. Beyond the preparation of high-nanoparticle content resists, we may encounter optical effects during two-photon direct writing. This is because most nanoparticles that are introduced are optically active themselves, plus they will contribute to higher local heating upon interaction with the laser. This work suggests that such adverse optical and thermal effects could be lessened through the use of three-photon initiated polymerization.

Background and Challenges in DLW

DLW typically uses two-photon absorption mechanisms, with laser wavelengths of 750-800 nm. This approach presents challenges when working with QD-polymer photoresists, particularly those containing near-infrared QDs like PbS. These materials show linear absorption at wavelengths above 800 nm, potentially leading to thermal effects, reduced penetration depth, and rapid laser power attenuation. These factors can affect the quality and resolution of the fabricated structures.

Three-Photon Polymerization: An Alternative Approach

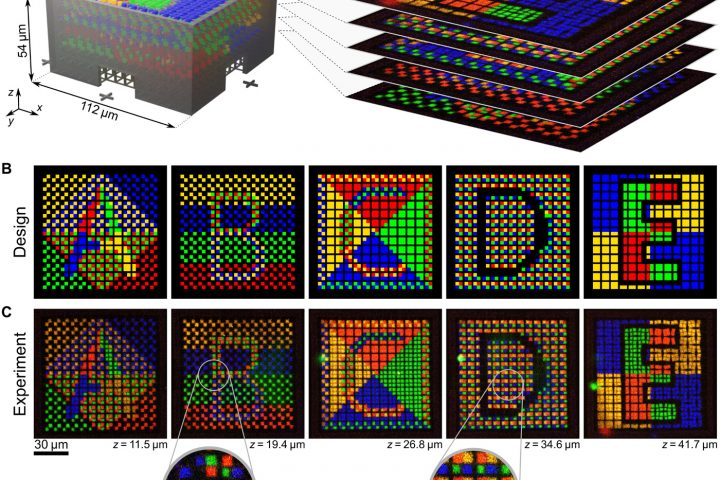

To address the limitations of two-photon processes, the researchers introduced a three-photon DLW technique using a 1035 nm wavelength laser. This approach aims to avoid the linear absorption issues associated with two-photon processes, potentially allowing for deeper penetration into the QD-polymer photoresist. The study suggests that three-photon absorption may enable the creation of high-resolution structures with different optical properties.

Photoinitiator Selection: Michler’s Ketone

The researchers selected Michler’s Ketone as the photoinitiator for the three-photon polymerization process. This compound exhibits absorption characteristics at the three-photon energy level. When excited by the 1035 nm laser, Michler’s Ketone generates free radicals that initiate the polymerization of the surrounding photoresist. This process is reported to facilitate the formation of micro/nano structures and allow for the emission of upconversion fluorescence.

Results and Findings

note: the slopes of ~2.9 in the log plots c and f can be approximated to 3 which means the phenomenon is associated with a 3 photon absorption,

- Fluorescence Intensity and Laser Intensity Relationship: The researchers report a cubic relationship between the fluorescence intensity and the incident laser intensity, which they interpret as confirming the nonlinear nature of the three-photon absorption process.

- Resolution and Structure Integrity: The results indicate that the three-photon DLW achieved resolutions with the finest line width reaching 58 nm. The fabricated structures reportedly exhibited certain mechanical properties and structural integrity.

- Morphological Consistency: The study evaluated the repeatability, size, and resolution of the filters by preparing circular filter arrays of different sizes and resolutions. The circular filters are reported to have remained physically intact after development, with uniform and consistent morphologies.

Potential Advantages of Three-Photon DLW

The researchers suggest several potential advantages of three-photon DLW over traditional two-photon methods:

- Resolution: The three-photon process may allow for the fabrication of structures with finer details.

- Penetration Depth: The longer wavelength used in three-photon DLW might enable deeper penetration into the photoresist.

- QD Concentration: The study reports successful use of QD-polymer photoresists with higher doping concentrations.

- Thermal Effects: By potentially minimizing linear absorption, the three-photon process might reduce thermal effects that can affect the quality of the fabricated structures.

- Design Flexibility: The ability to process materials with longer wavelengths may allow for different approaches in designing micro/nano structures.

Potential Applications of QD-Polymer Filters: Sensors, Waveguides, modulators

Conclusion

The research by Jiubin Jue and Zongsong Gan explores the use of three-photon polymerization in the fabrication of QD-polymer filters. By using this approach, the study aims to address certain limitations of traditional two-photon processes. The findings may contribute to the understanding of three-photon absorption mechanisms and could potentially lead to applications in photonics and related fields.

Reference

Direct Laser Writing of Micro–Nano Filters Based on Three-Photon Polymerization